What is Rebar?

Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar’s surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

What is the process of rebar production?

Rebar, predominantly made from steel due to its superior tensile strength compared to concrete, is often produced using recycled steel. This includes materials like scrap cars, appliances, and machinery which are melted down using electric arc furnaces. This molten steel is then cooled and shaped into billets for storage. When it’s time to create the rebar, these billets are reheated to a high temperature, though not to the point of melting, and quickly passed through a series of extrusion tools. Throughout these stages, the steel billet’s diameter is progressively reduced until it reaches the intended rebar diameter. Special tooling is used to create deformations in the rebar to ensure it grips the concrete and prevents slippage. Finally, the rebar is cut to the required length.

How does rebar work?

Rebar functions by combining the tensile strength of steel with the compressive strength of concrete, resulting in structures that possess a combination of both types of strength. This blend of strengths minimizes the risk of fractures and enhances the structure’s ability to withstand movements and forces that could potentially cause a concrete structure to fail. Rebar is commonly placed in a grid pattern, with segments positioned parallel and perpendicular to each other. This arrangement enables the rebar to withstand tensile forces from multiple directions. The deformations on the outer surface of the rebar prevent it from slipping out of the concrete structure. At times, the ends of the rebar are bent to provide additional anchoring within the concrete structure.

Rebar Sizes and the Usage

Rebar, also known as reinforcing steel or reinforcement steel, comes in a variety of sizes, each used for different purposes in construction. The sizes range from #3 rebar to #18 rebar, with the number corresponding to the bar’s diameter in eighths of an inch. For instance, #3 rebar has a diameter of 3/8-inch while #8 rebar has a diameter of 1 inch. Smaller sizes such as #3 and #4 rebar are typically used in residential construction for reinforcement in concrete slabs, driveways, and patios, while medium sizes like #5 to #7 rebar are commonly used in commercial construction for reinforcing large-scale structures like bridges and high-rise buildings. The largest sizes, such as #14 to #18 rebar, are mostly used in heavy civil construction for highway and freeway structures, as they provide the maximum amount of reinforcement.

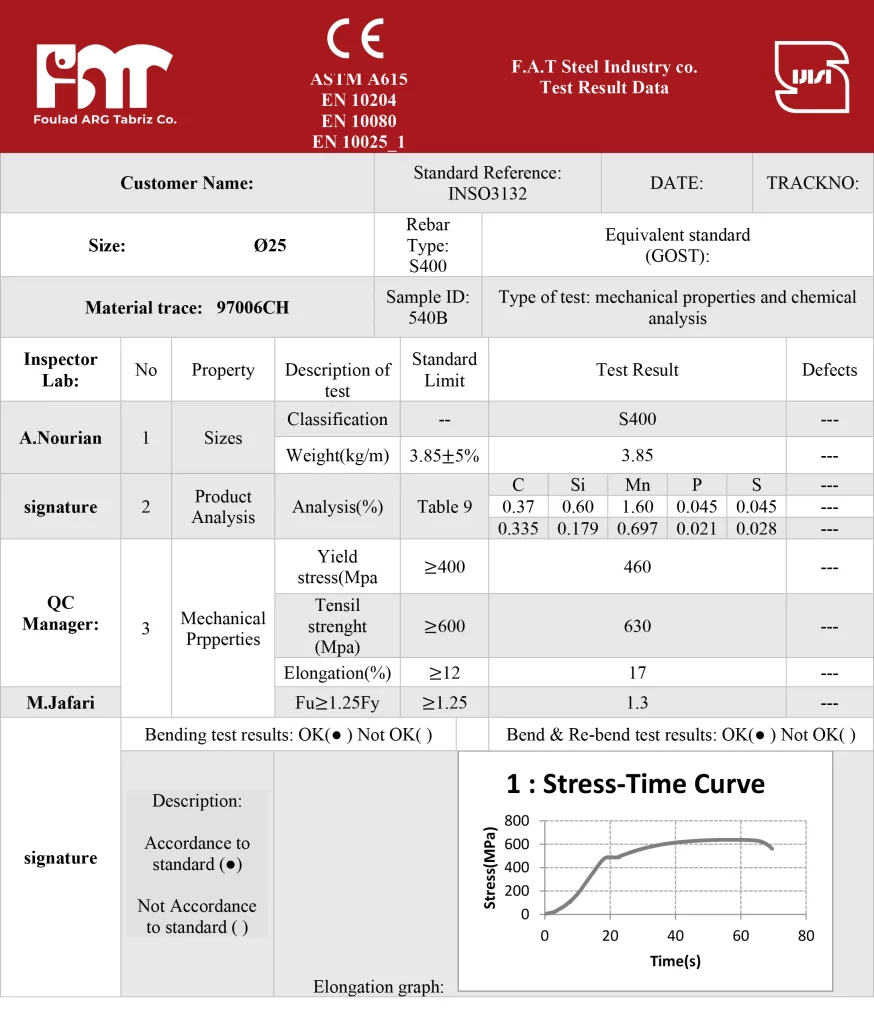

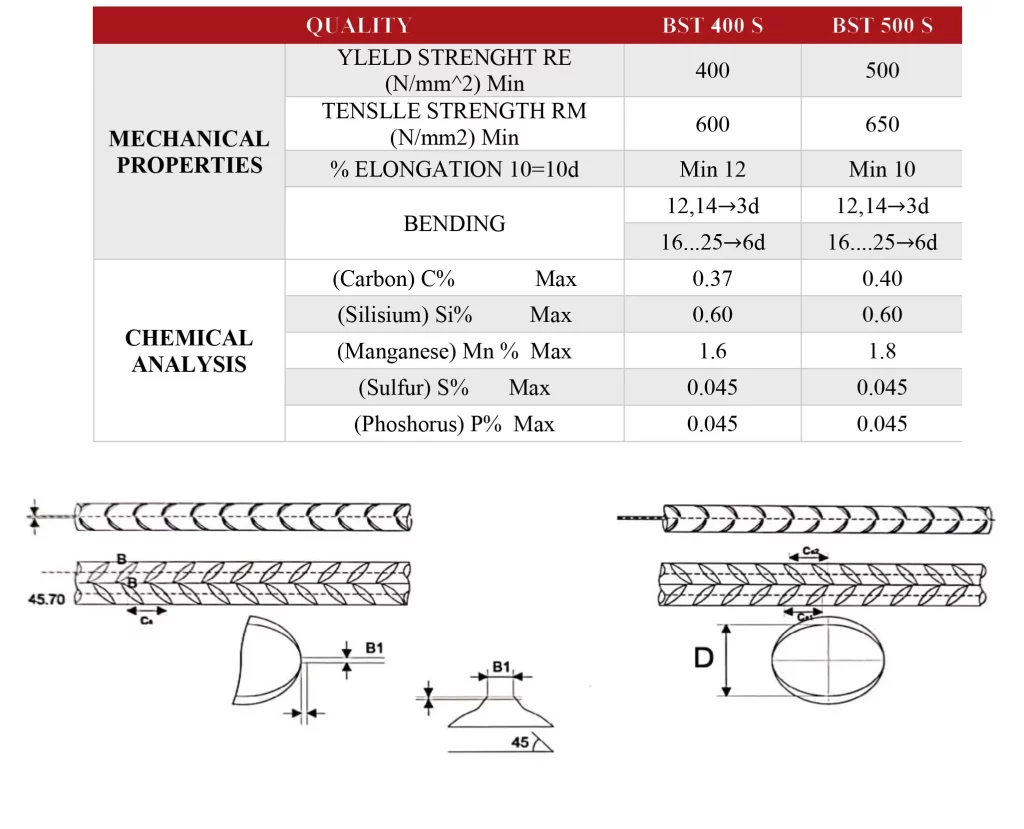

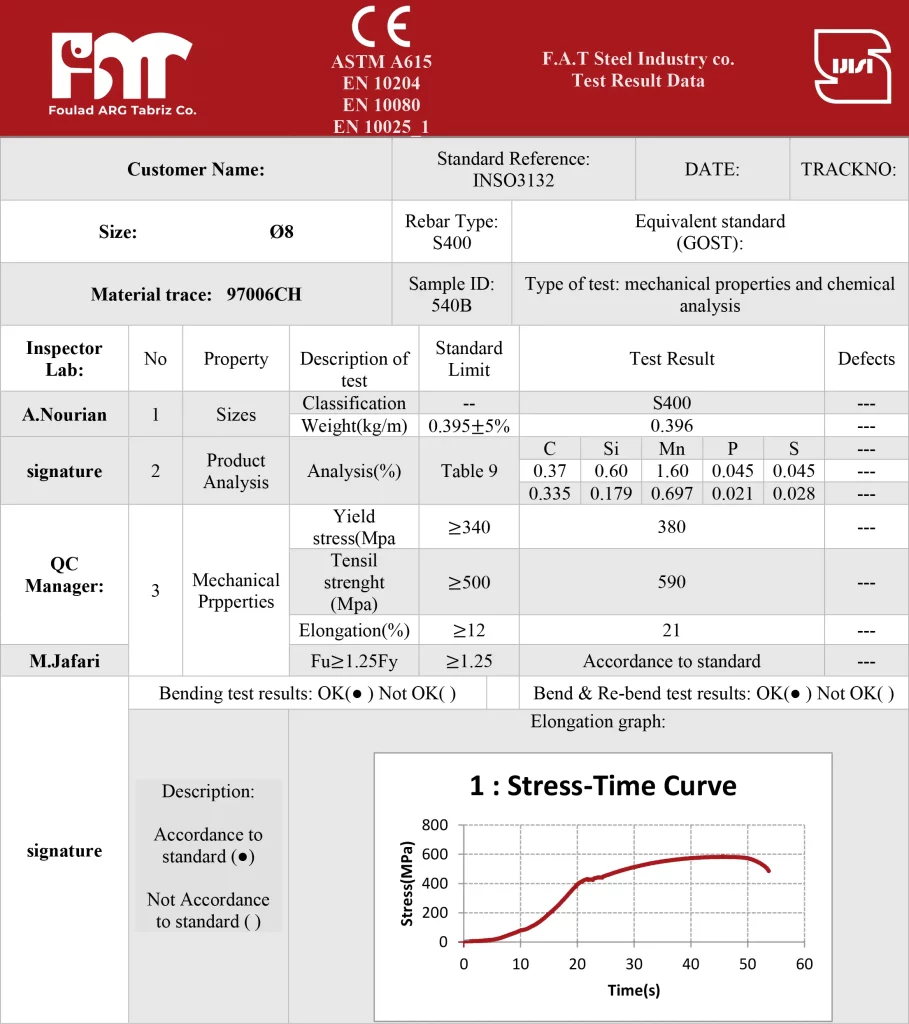

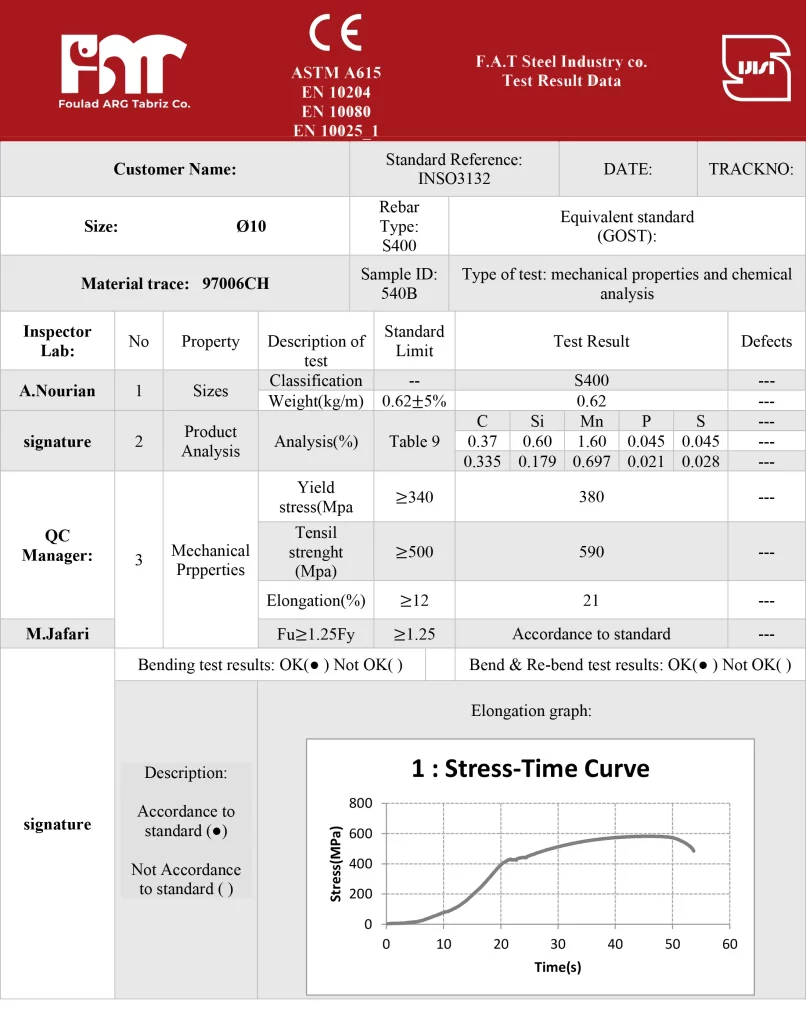

Foulad Arg Tabriz produces rebar in three main categories: S350, S400, and S500, each with related grades and subcategories.

Rebar Quality

S350 8

S350 10

S400 10

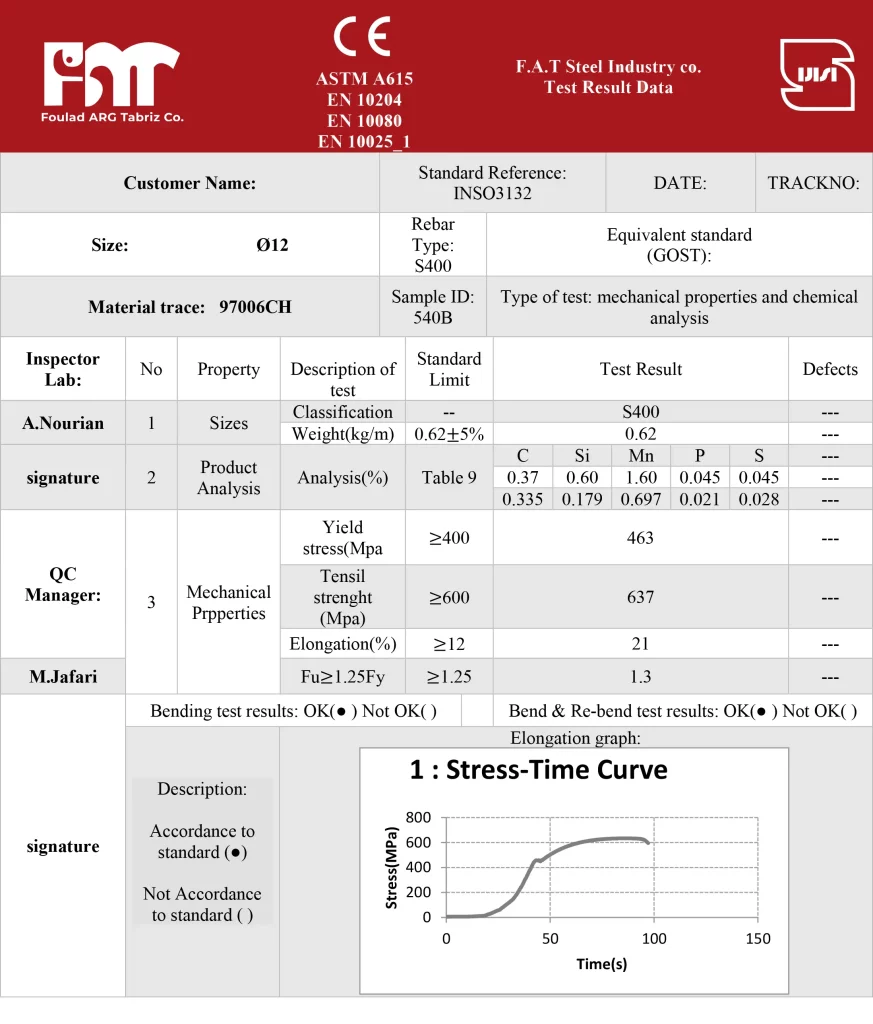

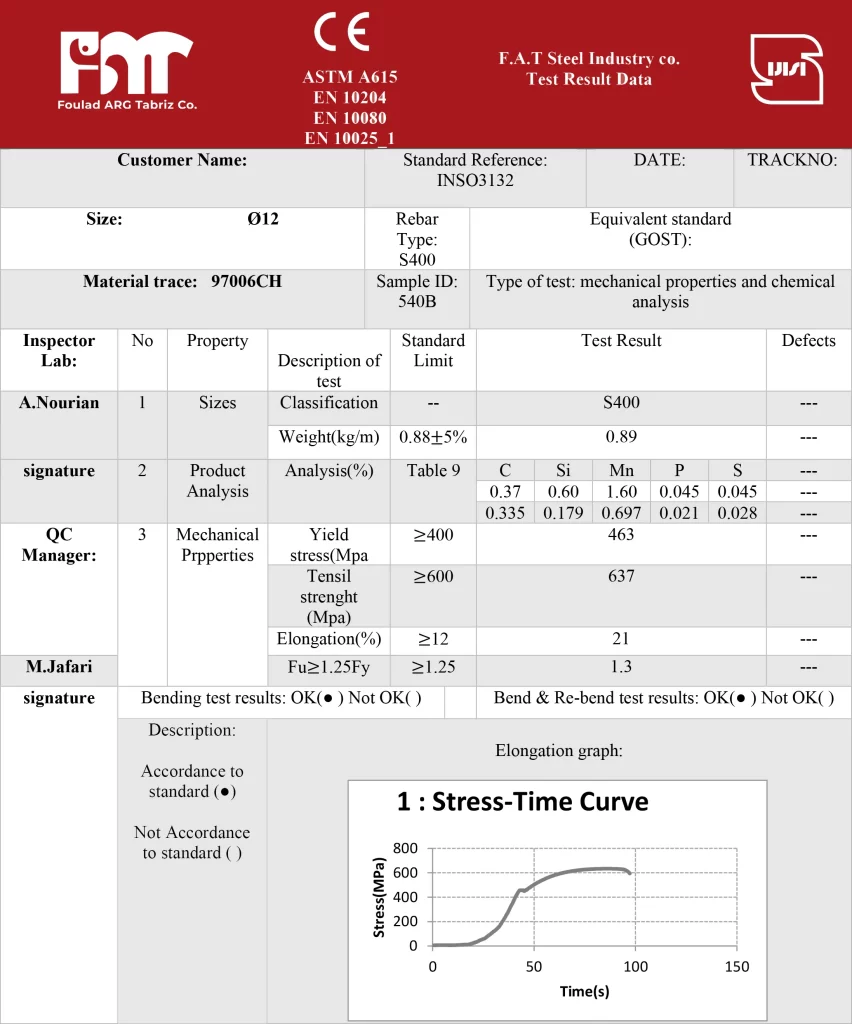

S400 12

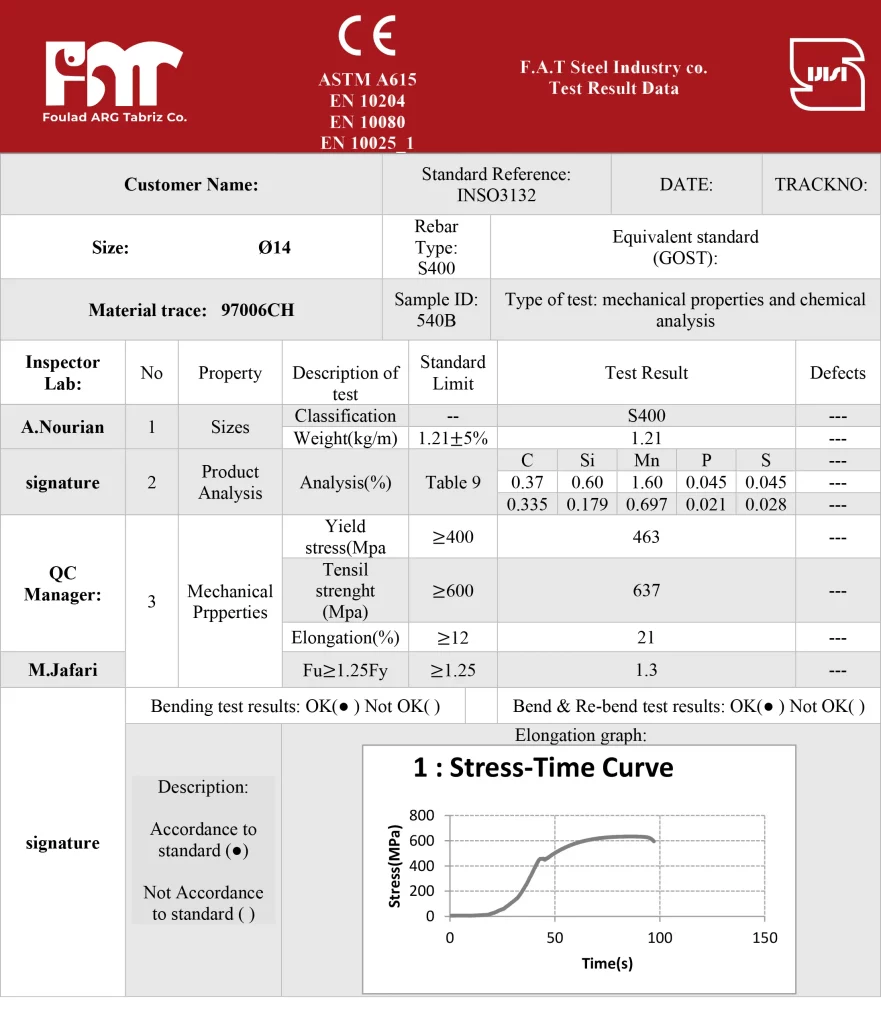

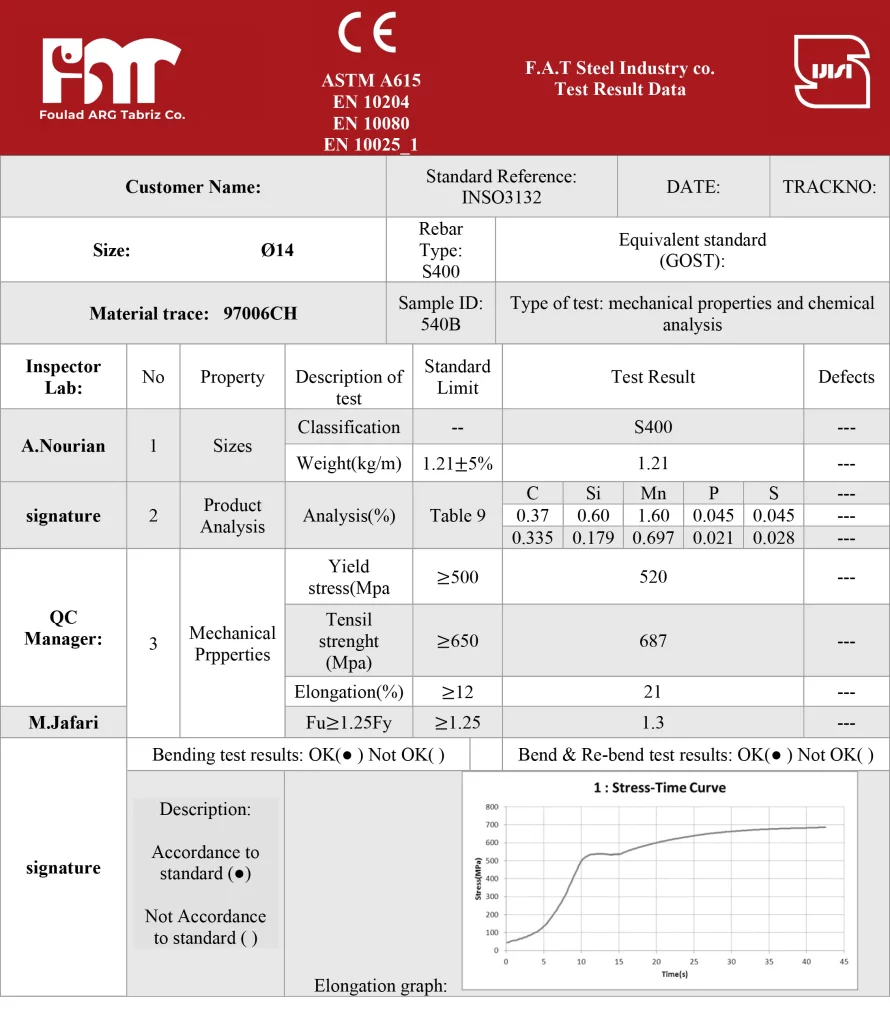

S400 14

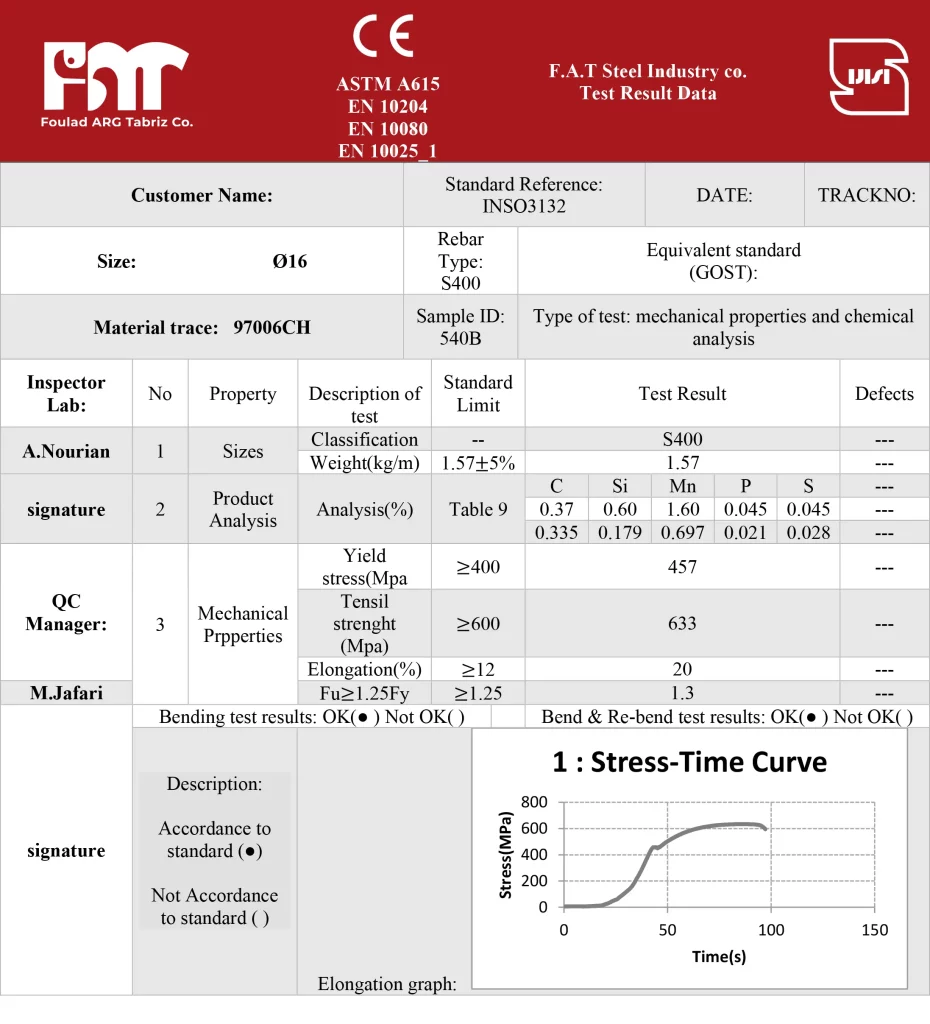

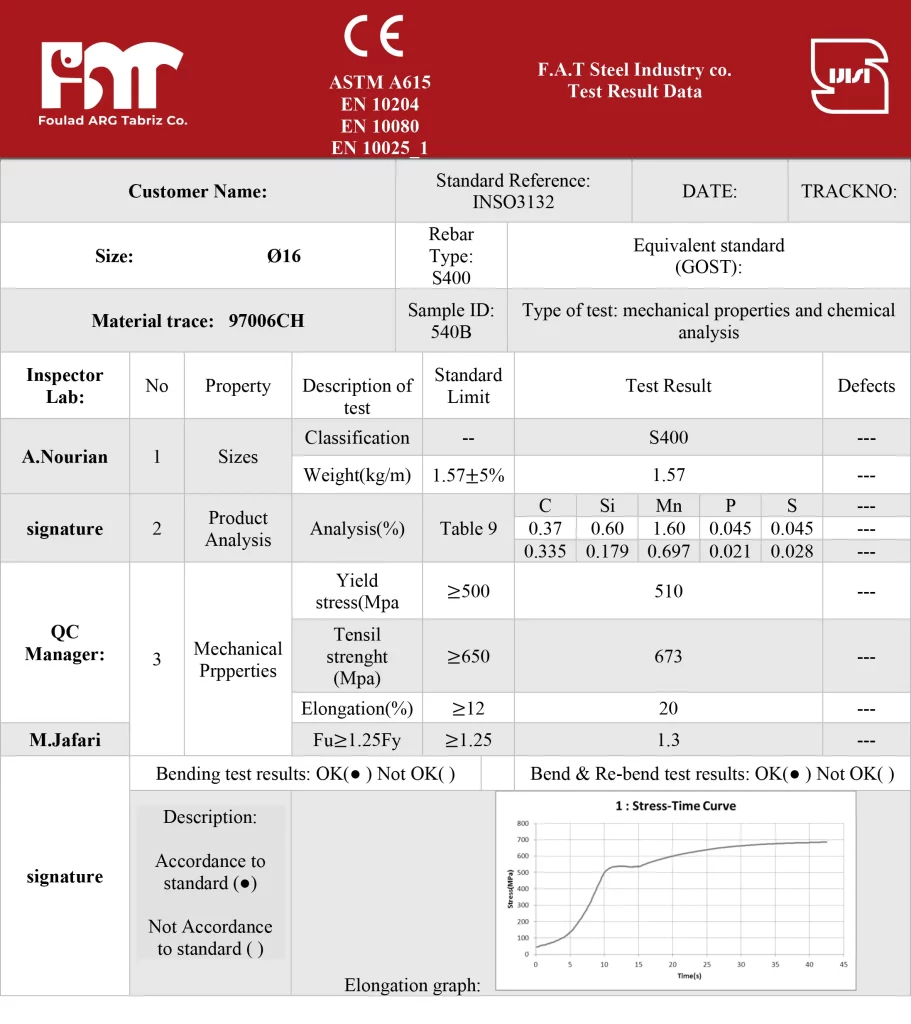

S400 16

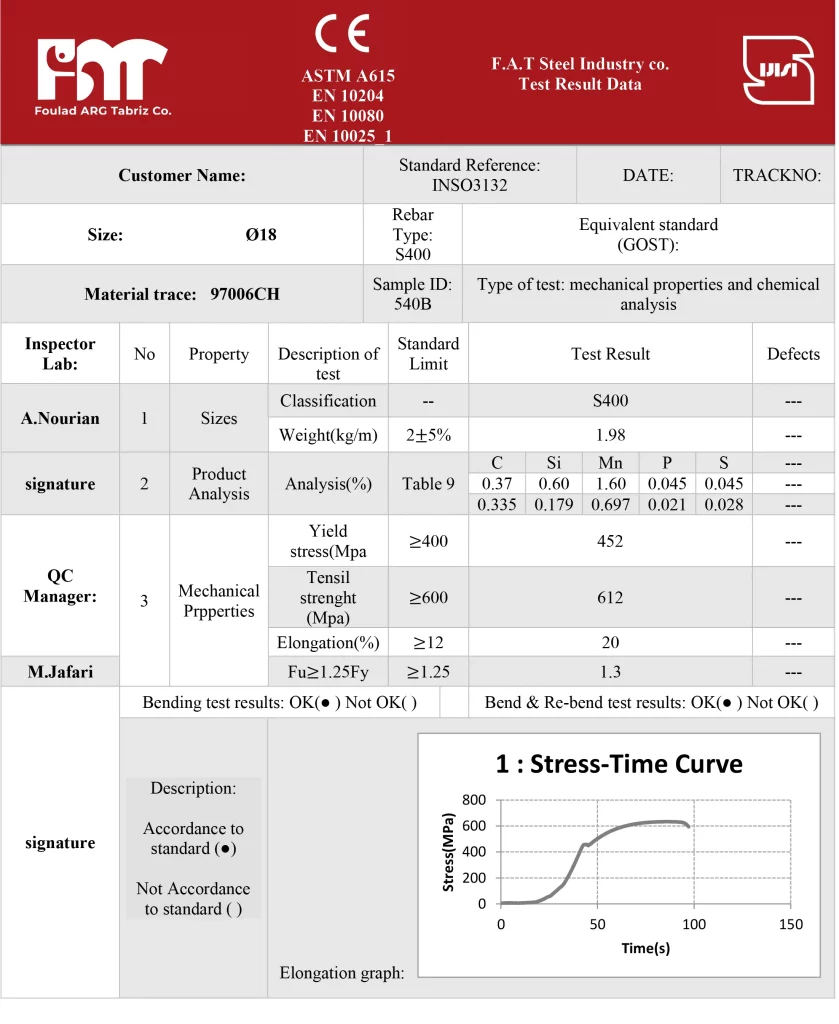

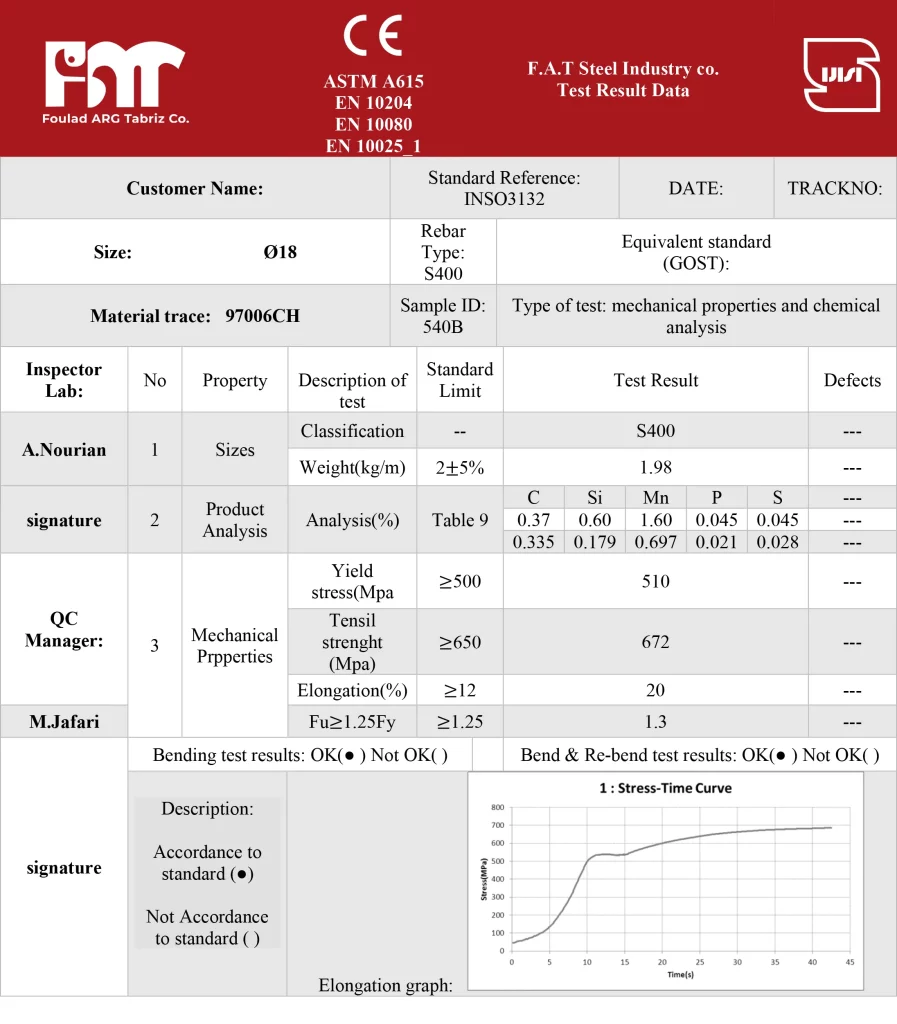

S400 18

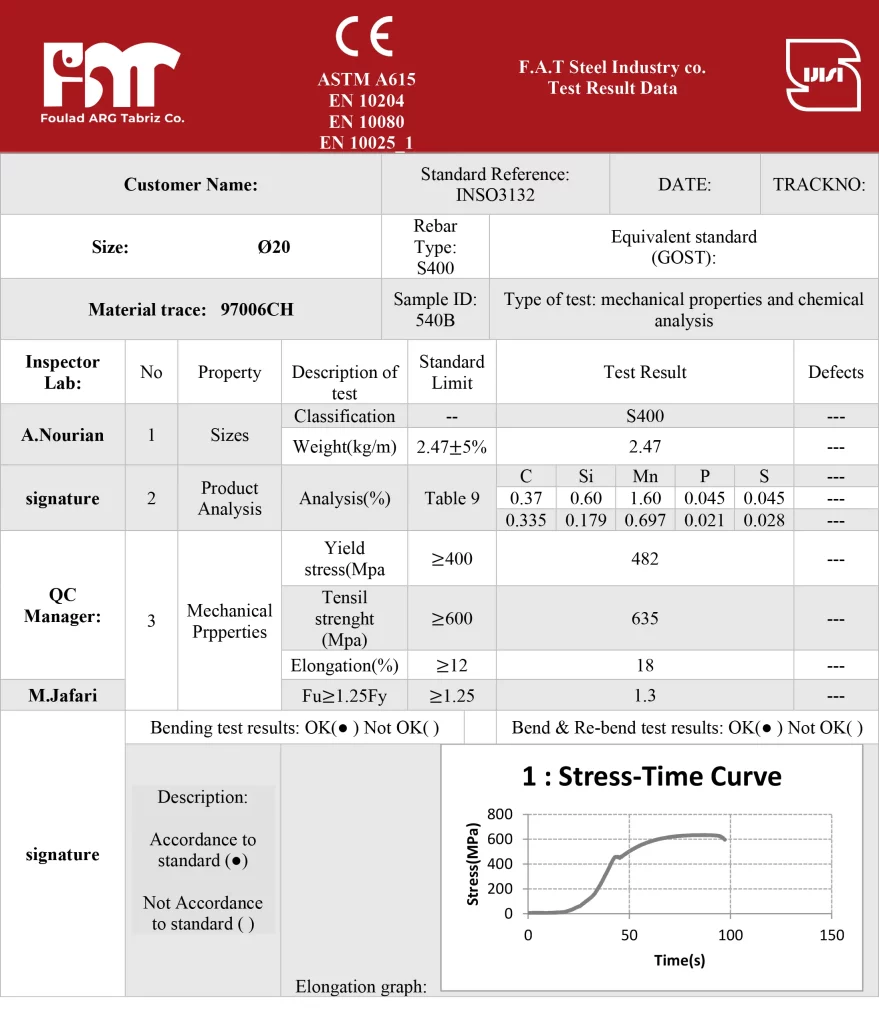

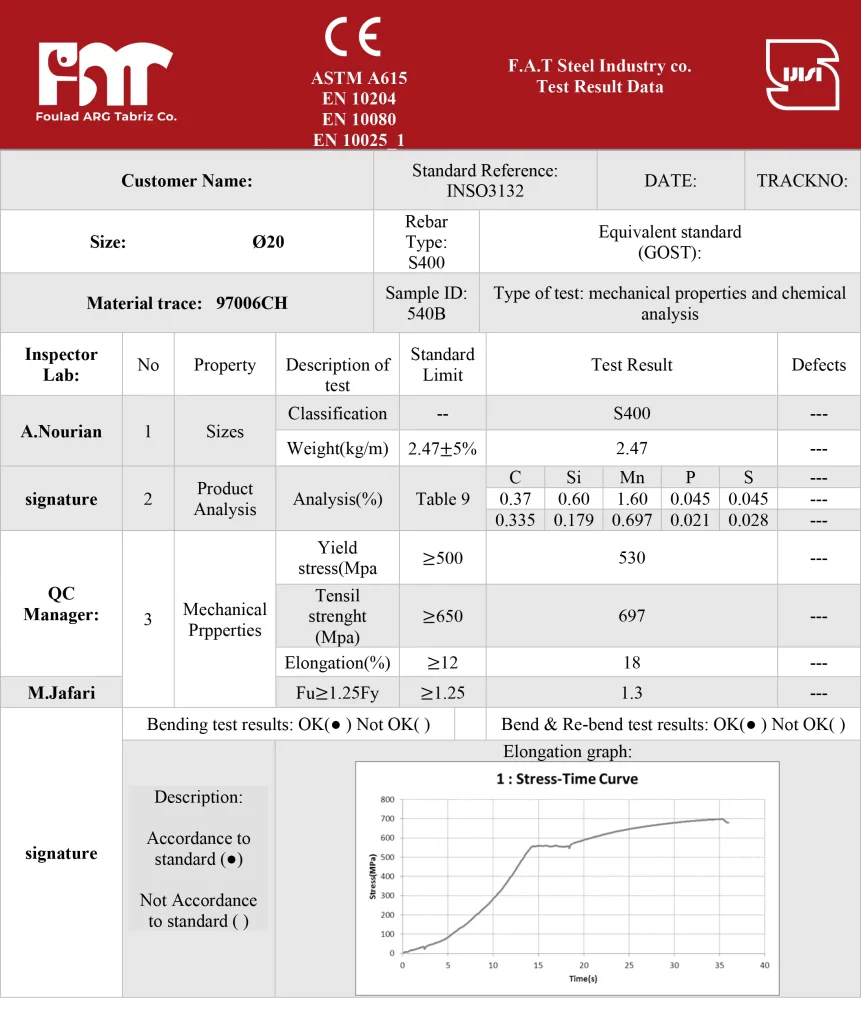

S400 20

S400 22

S500 14

S500 16

S500 18

S500 20

S500 22

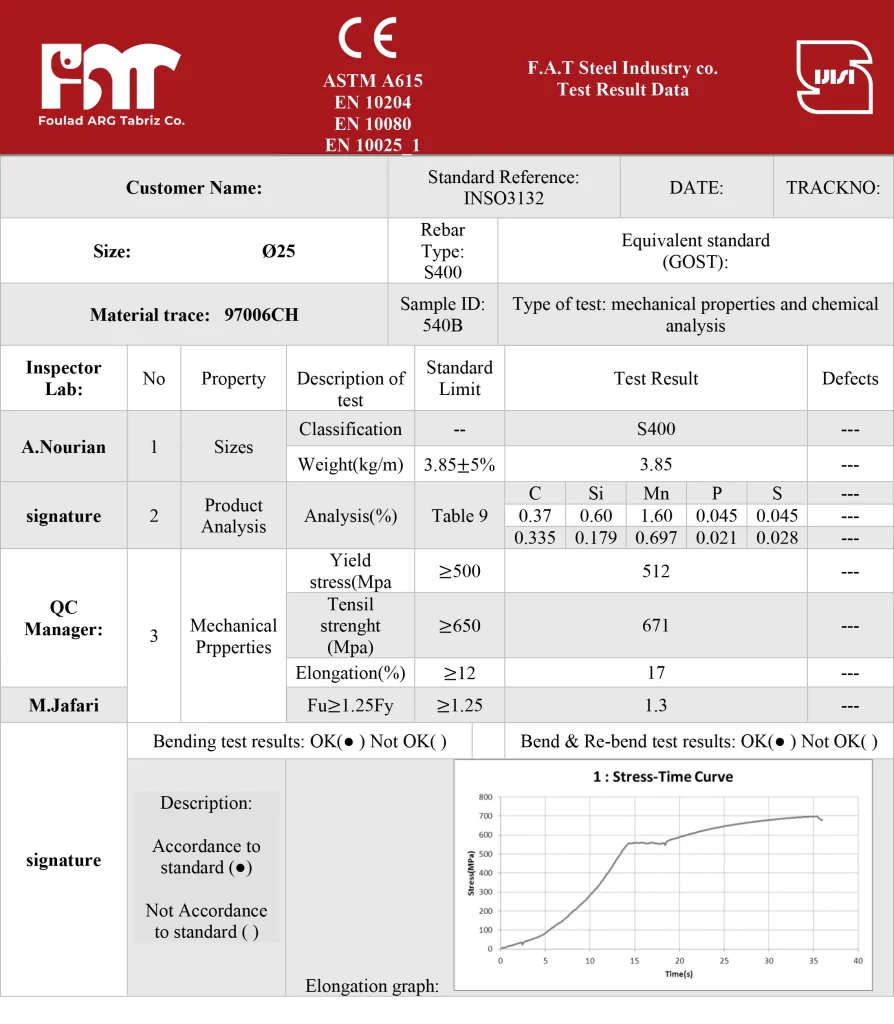

S500 25