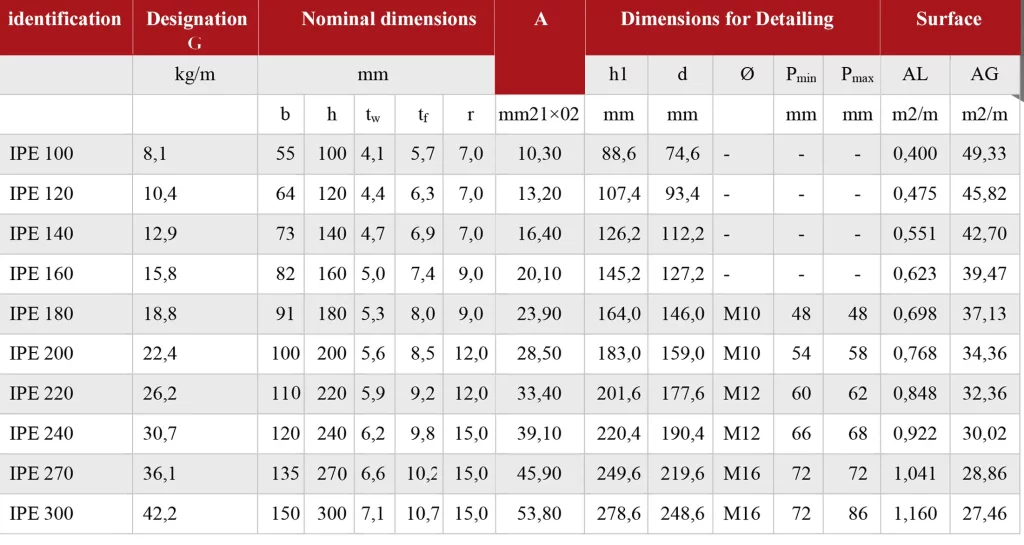

IPE, an abbreviation denoting bar-shaped building elements or beams with parallel internal surfaces of the flanges, adheres to dimensions specified in EN 10365, with product tolerances defined by EN 10034: 1993. The construction of a stainless steel beam can either involve welding together its individual components or opting for hot rolling or extrusion. In this structural marvel, the upper and lower horizontal components are known as flanges, while the connecting vertical middle part is aptly named the web. The standard IPE profile stands out as the most prevalent in this product category, with the lighter IPE AAAA to A versions and the heavier IPE O being less commonly employed.

Stainless steel IPE beams find applications not only in commerce and industry but also in machinery and equipment building. The allure of stainless steel profiles lies in their remarkable flexibility in composition, facilitating swift and cost-effective construction—thanks to the option of prefabrication during steel production. Additionally, the production process of stainless steel profiles predominantly relies on recycled scrap materials, ensuring the potential for recycling once these profiles reach the end of their lifespan. This sustainable practice plays a crucial role in conserving valuable resources for future use.